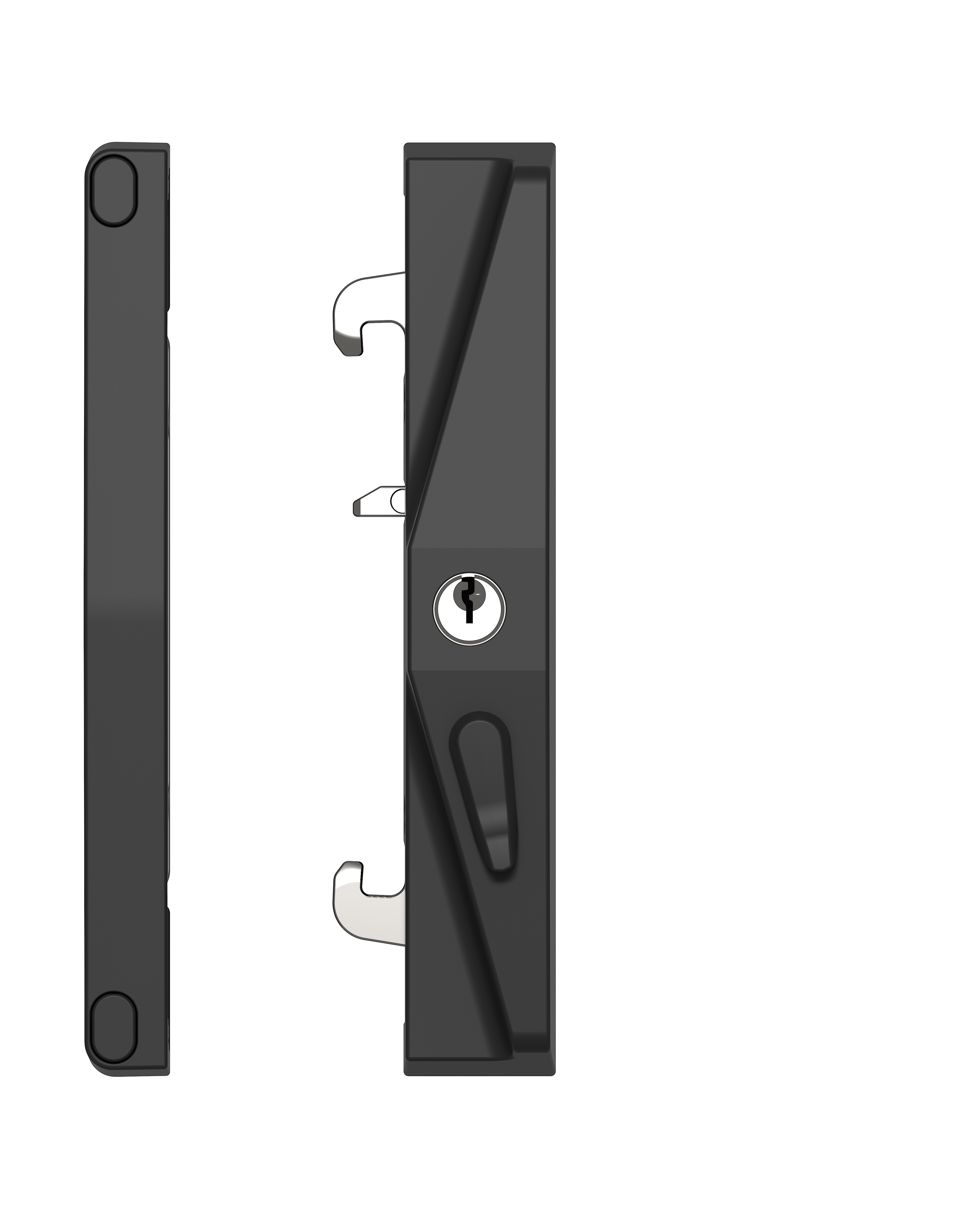

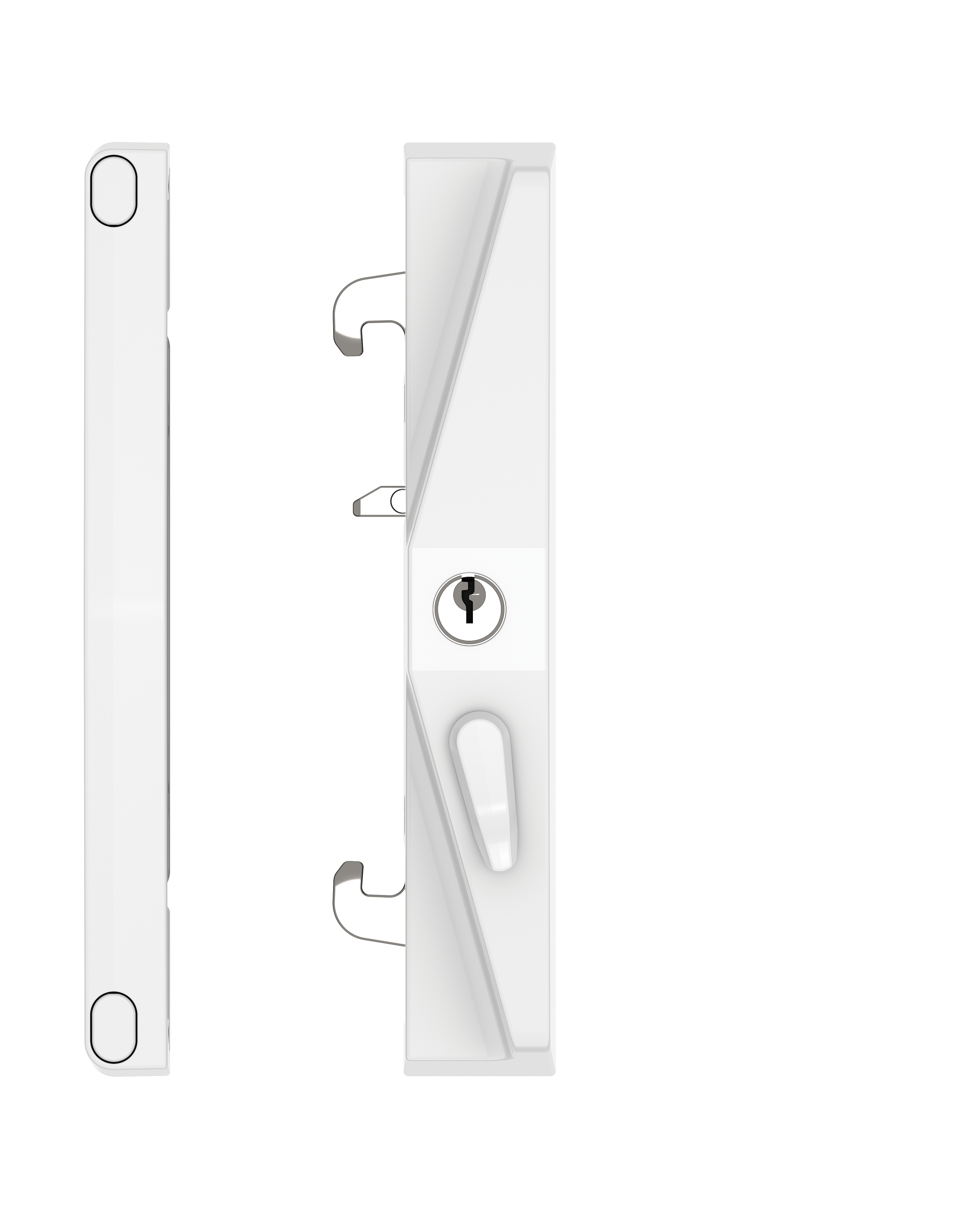

Forge Sliding Patio Door Surface Mount Slim Lock

The Forge Sliding Patio Door Slim lock is an Australian made, all-metal lock for sliding glass doors.

Part the Forge family of products, the sliding patio door features clean, fresh lines and a slim design for doors with a large stiffening wing or narrow frame.

Available in Black (BLST). Can be powder coated to almost any Dulux or Interpon colour at our Melbourne based facility.*

Description

Product Features

- Slim profile provides minimal interruption of door opening

- Non-deadlockable on outside only cylinder configuration for flexible application

- Austral Lock cylinders available for versatile locking configurations, including external key locking with internal snib unlocking

- Twin counteracting beaks engage an all metal catch plate, providing resistance to jemmying & restraining door being lifted from its rails

- Anti-slam plunger prevents door being shut with beaks extended, avoiding damage to beaks & catch plate

- Self adjusting strike with 16mm or 25mm colour matched cover suitable for face fixing as well as jamb fixing

- Self-adjusting catch plate automatically compensates for building movement and door carriage wear

- Fits industry-standard cutouts

- Fits wide range of door stile thicknesses from 21mm to 46mm

- Suits left-closing and right-closing doors (lock is not handed)

- Australian designed and manufactured

- 7 year limited tarnish resistant and 10 year limited mechanical guarantee

*Colour matched hardware is locally manufactured, and can be powder coated to standard 24 finishes available on Austral Lock colour chart, any other finish may attract additional costs and longer lead times.

Colour Chart

Installation

The product must be installed according to the instructions included in the product packaging and the door should be apertured according to the door “cut-out” dimensions and tolerances shown.

Prior to fitting ensure that:

- Doors stored on site are stored in a clean dry area free from cement, lime, paint, acid etc.

During fitting of the lock ensure that:

- No metal swarf or other contaminants enter the lock body.

- The fixing screws do not damage the product finish.

After installation of the door ensure that:

- The door is correctly adjusted with the correct clearances.

- The lock engages the strike/catch plate correctly.

- The door is protected from building fall-out such as wet plaster, mortar, paint and welding splatter.

If the door becomes contaminated:

- Do not paint the lock body or faceplate.

- Remove wet plaster, cement, mortar and other droppings immediately, using ample clean water and a sponge or rag, to avoid permanent staining or scratching of the product finish. If removal is delayed and scraping becomes necessary the surface finish may suffer.

Maintenance & Cleaning

Maintenance

Annually inspect the door to confirm that the door operates with the correct clearances, closes and opens without obstruction. Confirm that the lock bolt or beak engages easily with the strike/catch plate when the door is closed and the lever or key is turned – adjust the door if necessary.

Annually check that when the door is closed, the lock can be locked by key and by the lever.

NB : The lock assembly has been lubricated for life, and should not be disassembled by the user.

Cleaning Powder Coatings

Every six months, powder coated surfaces should be cleaned to protect the finish. However, in areas where pollutants are more prevalent, especially in coastal or industrial regions, cleaning should be carried out every two to three months.

To clean the powder coated surface:

- Carefully remove any loose deposits with a wet sponge.

- Use a soft brush (non abrasive) or cloth and a mild household detergent solution to remove dust, salt and other deposits. Do not use steel wool, scrapers, scouring liquids or powders to remove deposits as these permanently scratch the coating surface.

- Rinse off with clean fresh water.

Cleaning Chrome, Satin Chrome, Gold and Brass Finishes

Plated finishes are susceptible to tarnishing if they come into contact with moisture, wet paint, or water vapour.

All plated finishes should be coated with a non-abrasive furniture or car wax immediately after installation.

Plated finishes should be regularly wiped with a non-abrasive furniture or car wax, taking care not to scratch any protective finishes that are employed to protect the surface and prevent tarnishing.